DOUBLE WING HINGED COLD ROOM DOORS

Behind This Door Isn’t Just Cold, It’s Safe

Double Wing Hinged Cold Room Doors

What Are Double Wing Hinged Cold Room Doors?

Double Wing Hinged Cold Room Doors are specialized hinged doors designed for cold storage environments that require the storage and transportation of large or bulky items. These doors feature a dual-wing design, allowing one wing to operate as a standard hinged door while enabling both leaves to open simultaneously. This flexibility facilitates the easy movement of large loads on trolleys, enhancing operational efficiency and accessibility within the cold room.Importance of Double Wing Hinged Doors in Cold Storage

Maintaining consistent and efficient cooling is essential in cold storage facilities to preserve product quality, extend shelf life, and ensure operational efficiency. Double Wing Hinged cold room Doors play a vital role in:- Facilitating Large-Scale Storage: Ideal for storing and transporting large or multiple product packs, ensuring easy access and handling.

- Enhancing Energy Efficiency: Superior insulation minimizes heat transfer, reducing energy consumption and maintaining stable internal temperatures.

- Maximizing Space Utilization: The dual-wing design optimizes space within the cold room, allowing for better organization and increased storage capacity.

- Ensuring Durability and Longevity: Constructed with high-quality materials, these doors withstand the rigors of cold environments and heavy usage.

Features of Tunelgroup’s Double Wing Hinged Cold Room Doors

Double Wing Hinged Cold Room Doors are equipped with a range of advanced features designed to deliver superior performance and reliability:

- Dual-Wing Design: Allows one wing to operate as a standard hinged door and both leaves to open simultaneously for transporting large loads.

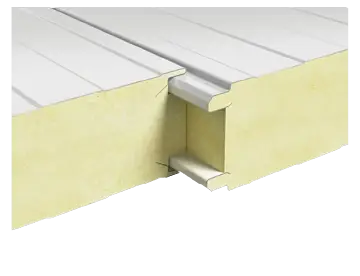

- High-Quality Construction: Doors are made from 0.5 mm thick steel sheets with rigid polyurethane foam cores (density up to 50 kg/m³) for excellent thermal insulation.

- Durable Metal Frames: Anodized aluminum frames prevent heat transfer and corrosion, ensuring long-term durability.

- Customizable Options: Available in galvanized steel painted with RAL 9003, unpainted galvanized steel, AISI 430 stainless steel for non-food facilities, AISI 304 stainless steel for food facilities, and food-safe laminated steel.

- Enhanced Security: Equipped with Rahrbach 7501 internal and external locks, and Rahrbach 7514 door hinges for secure and reliable operation.

- Vibrationless Operation: Features an EPDM rubber sealing system and vibration dampening elements to minimize noise and enhance stability.

- Advanced Sealing Systems: Dual rubber gaskets made from EPDM rubber ensure airtight sealing, preserving internal temperatures and preventing moisture ingress.

- Built-In Heating Elements: 220V, 25W/m silicone-based resistors prevent ice buildup, ensuring smooth door operation in frozen storage environments.

- Easy Installation: Doors are wrapped in a protective 50 μm thick film for safe transportation and easy installation, with no need for additional counter-frames or panel closings.

Benefits of Tunelgroup’s Double Wing Hinged Cold Room Doors

Implementing Double Wing Hinged Cold Room Doors offers numerous advantages that enhance both the functionality and efficiency of cold storage facilities:

- Superior Thermal Insulation: High-density polyurethane foam cores minimize heat transfer, maintaining consistent internal temperatures.

- Energy Efficiency: Advanced insulation and sealing systems reduce energy consumption, leading to significant cost savings over time.

- Enhanced Durability: Constructed with high-quality materials and protective coatings, these doors offer long service life even in demanding environments.

- Versatile Functionality: Dual-wing design allows for flexible operation, accommodating both standard and large-scale storage needs.

- Hygienic and Safe: AMB (antimicrobial) surfaces and food-safe gaskets ensure a sanitary environment, essential for food storage and processing.

- Quiet and Stable Operation: Vibrationless design and ultra-quiet fan options create a more comfortable and productive working environment.

- Easy Maintenance: Removable components and robust construction simplify maintenance tasks, reducing downtime and operational disruptions.

- Customizable Aesthetics: Available in various colors and finishes to match facility aesthetics and specific operational requirements.

Gaskets and Seals

Advantages of Tunelgroup’s Double Wing Hinged Cold Room Doors

- Produced in Accordance with World Standards: Ensures compliance with international quality and safety regulations.

- Highly Efficient Cooling: Advanced insulation technology delivers superior cooling performance.

- Quality and Reliable Equipment: High-quality components guarantee long service life and dependable operation.

- Easy Installation and Assembly: Simplified setup processes save time and reduce operational downtime.

- Adaptable to Different Mounting Styles: Flexible design accommodates various installation environments.

- External Cabin Unit for Easy Maintenance: Facilitates straightforward maintenance, minimizing downtime.

- HACCP Compliance: Meets stringent hygiene and safety standards, essential for food storage and processing.

- Evaporator Design Minimizes Moisture Loss: Protects the integrity of stored products by reducing moisture loss.

- Energy Savings: Extends defrost intervals and reduces the number of defrosts, enhancing energy efficiency.

- Reduced Operating Costs: Long cooling periods without defrosting lower overall operational expenses.

We manufacture industrial cooling systems panels, doors, cooling devices and ice machines under one roof!

TUNELGROUP PRODUCTS

Cold Storage Pioneer in Industrial Design

Manufacturing and Sales of Industrial Cold Storage Wall, Ceiling and Floor Panels

Manufacturing and Sales of Industrial Cold Storage Sliding, Hinged, Monorail and Flip-Flap Doors

Manufacturing and Sales of Split Type Hermetic, Semi-Hermetic and Double Stage Shock Devices for Industrial Cold Storage

Easy Installation Possibility with Modular Type Cold Rooms and Monoblock Cooling Devices

Manufacturing and Sales of Facade and Roof Panels for Exterior and Roof Covering of Industrial Warehouses

Manufacturing and Sales of Sectional, Office-Service and Fast Rolling Doors for Industrial Warehouses

Manufacturing and Sales of Industrial Cold Storage Ceiling Type and Standard Type Cooling Systems

Manufacturing and Sales of Ready-made System Container Cold Storages with Wall, Ceiling, Floor Insulation and Cooling Devices

We manufacture industrial cooling systems panels, doors, cooling devices and ice machines under one roof!

FIELDS OF ACTIVITY

Contracting, Service and Engineering

Tunelgroup Industrial Cooling Systems; Manufactures and Sells Industrial Cooling Systems Panels, Doors and Cooling Devices. With its high engineering principles and perception of quality, it offers its customers efficiency-based, respected and sustainable services. Our company; From planning to design, from the project process to investment, from development to turnkey completion, it offers engineering services and professional solution partnerships in your investments with our own production steel construction systems.

By combining innovation, sustainability, and expertise, Tunel Group delivers cold storage for meat solutions that not only guarantee optimal preservation but also align with modern energy efficiency and sustainability standards.

With a commitment to quality, innovation, and sustainability, Tunel Group ensures that poultry producers and distributors can optimize cold storage for chicken conditions while reducing operational costs, providing reliable and sustainable solutions for the seafood industry.

With a commitment to quality, innovation, and sustainability, Tunel Group optimizes cold storage for fish conditions while reducing operational costs, providing reliable and sustainable solutions for the seafood industry.

By combining innovation, sustainability, and expertise, Tunel Group delivers advanced cold room solutions for fruits that meet the highest industry standards, ensuring your fruits remain fresh and market-ready.

By combining innovation, sustainability, and expertise, Tunel Group ensures your vegetables are stored in optimal cold room for vegetables conditions, extending shelf life and preserving quality.

By combining innovation, sustainability, and expertise, Tunel Group ensures your dairy products are stored in optimal cold storage for dairy conditions, extending shelf life and preserving quality.

With a commitment to quality, innovation, and sustainability, Tunel Group ensures that bakery producers can optimize cold storage for bakery conditions while reducing operational costs.

Our cutting-edge flower cold rooms create the perfect environment for flowers, minimizing wilting, discoloration, and decay while enhancing their natural beauty and longevity.

Our cold room systems are meticulously engineered to address the unique requirements of the pharmaceutical sector, guaranteeing optimal storage conditions throughout the entire product lifecycle.

CONTACT US FOR DOUBLE WING HINGED COLD ROOM DOORS

„Contact us“

Fill in the form. We will contact you as soon as possible.Contact Us For Double Wing Hinged Cold Room Doors

Have questions or ready to take the next step? Contact us; we are here to help you on your cooling systems journey.

Working Time

Mon-Fri: 09:00 - 18:00

Closed on Weekends

İstanbul Factory

Dudullu Organize Sanayi Bölgesi, Nato Yolu Cd No:39, 34776

Y. Dudullu/Ümraniye/İstanbul

Bursa Factory

Kayapa, Kayapa OSB, 10. Sk. No:6, 16315

Ni̇lüfer/Bursa

Follow Us

Fill Out The Form For Double Wing Hinged Cold Room Doors

Whether you are looking for guidance, planning a cold room or simply want more information, we have you covered.

Our Mega Structure Design and Manufacturing Efficiency is at the Top Level with Knowledge, Experience and Effective Engineering